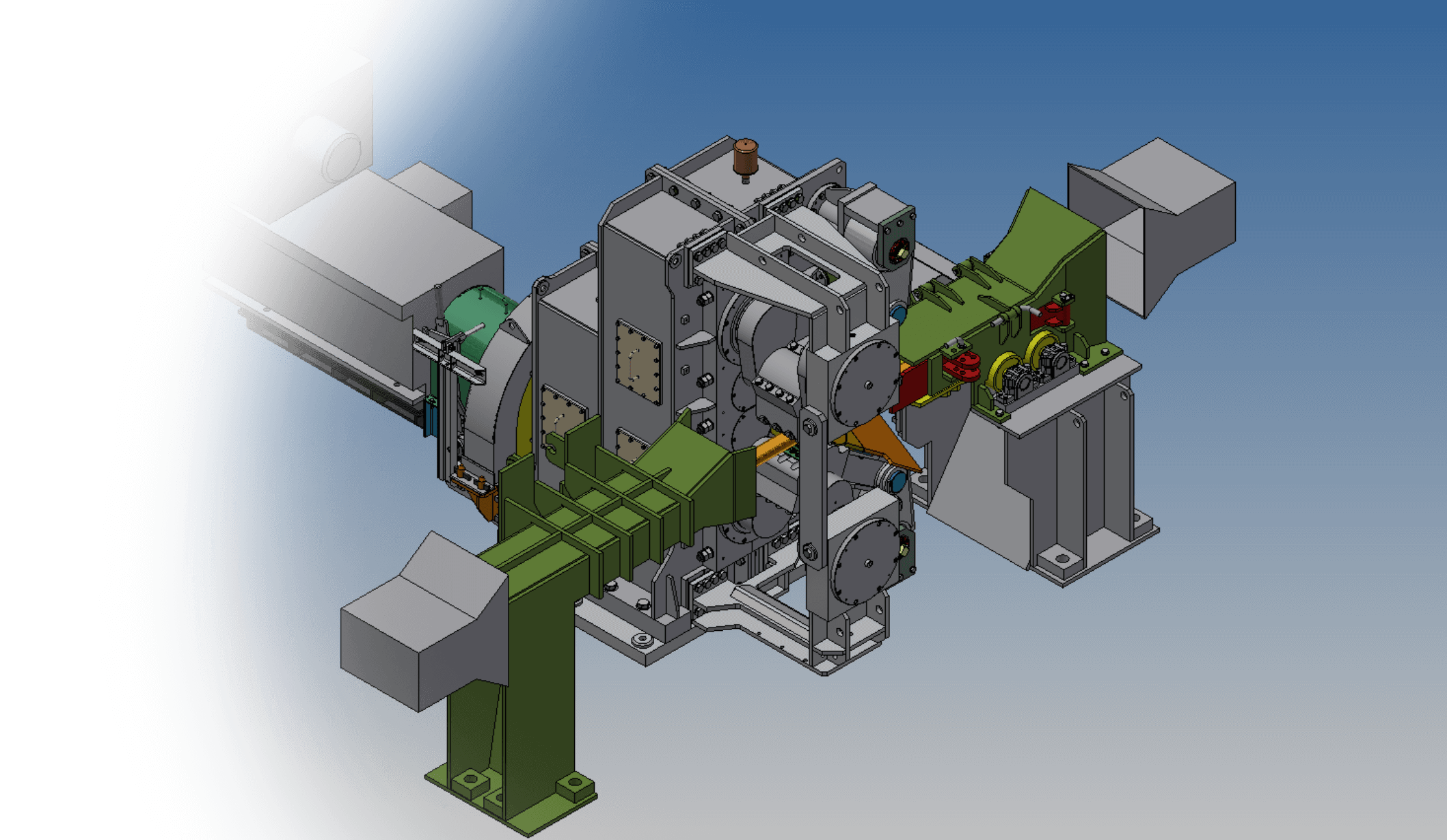

Revamping and shear replacement project for long products rolling mill

For this customer we have designed a new shear, having double cutting capacity of the previous one, in a record time of only 5 weeks. The main peculiarity of this project is that, through an appropriate sizing of all the parts that compose it, it has allowed the new shear to be installed on the same foundations and to reuse the same motor and relative drive of the existing shear. This design has led to enormously reduce installation and start-up times and costs.

Furthermore, this new shear has allowed, in a very short time, to increase both the hourly productivity and the range of products that can be cut. This performance was possible thanks to the great experience both in the dimensioning calculations sector and in the knowledge of the process it was also crucial the correct application of the FEM software for the control of the parts placed under stress. Previous experience in other similar projects has also contributed to achieving this goal